Electronic relays play a crucial role in various industries, from telecommunications to automotive engineering. Understanding how to make an electronic relay is essential for professionals in these fields. In this comprehensive guide, we will delve into the intricacies of electronic relays, covering their construction, working principles, and practical applications. By the end, you will have a solid foundation to design and create your own electronic relay.

- Understanding Electronic Relays:

1.1 Definition and Purpose:

Electronic relays are devices that control the flow of electric current by using an electromagnetic switch. They are commonly used to switch high-power circuits with low-power control signals.

1.2 Components of an Electronic Relay:

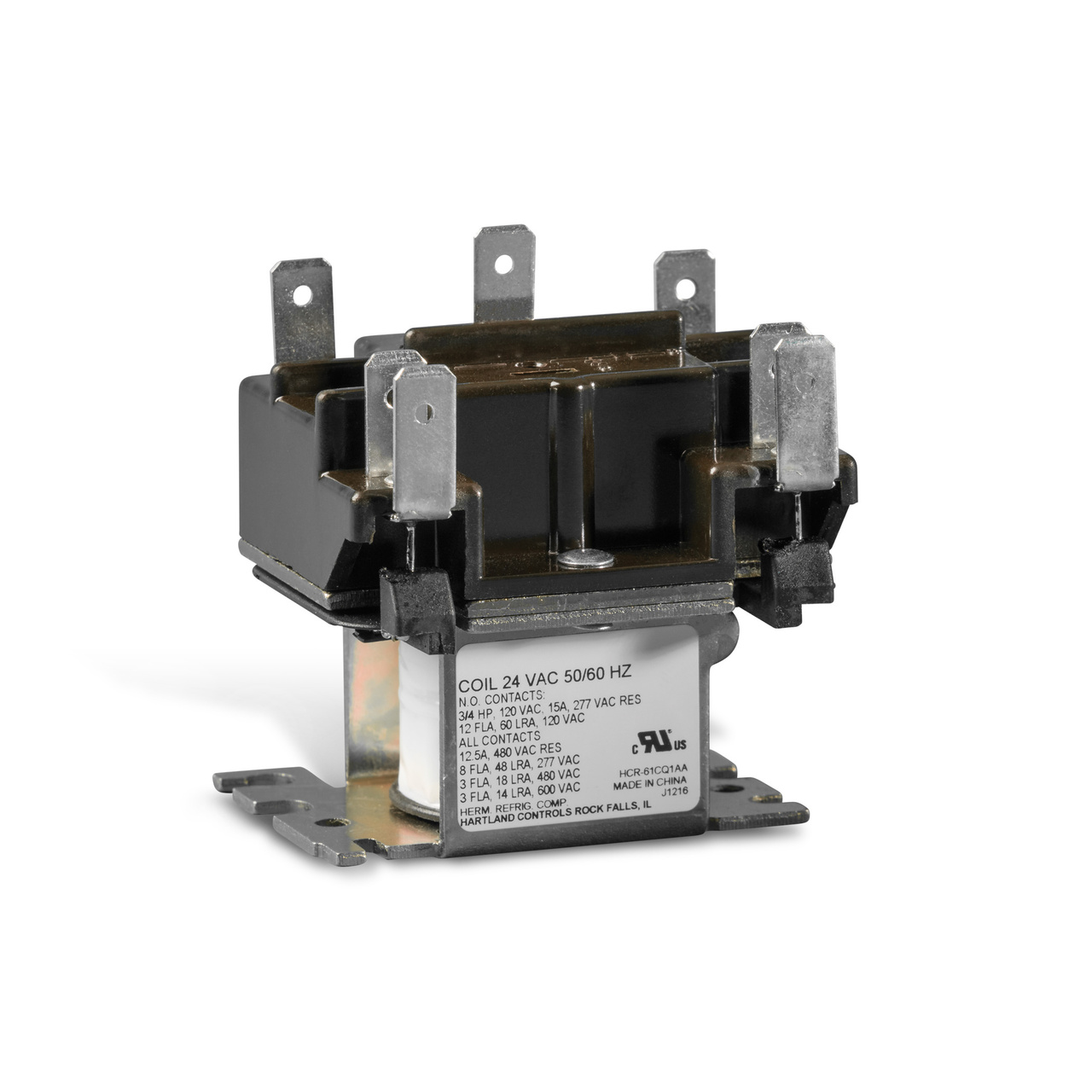

An electronic relay consists of several key components, including:

- Coil: The coil generates a magnetic field when an electric current passes through it.

- Armature: The armature is attracted to the coil when the magnetic field is present.

- Contacts: The contacts are responsible for opening or closing the circuit based on the position of the armature.

- Designing an Electronic Relay:

2.1 Selecting the Coil:

Choosing the appropriate coil is crucial for the relay's performance. Factors to consider include voltage rating, current rating, and coil resistance. Additionally, the coil material and construction should be selected based on the desired application.

2.2 Determining the Armature and Contact Configuration:

The armature and contact configuration depend on the specific requirements of the circuit. Options include normally open (NO), normally closed (NC), and changeover (CO) contacts. Careful consideration should be given to the load type, voltage, and current requirements.

2.3 Incorporating Protective Measures:

To ensure the reliability and longevity of the electronic relay, protective measures should be implemented. These may include surge protection, diode suppression, and thermal overload protection. Understanding the potential risks and incorporating appropriate safeguards is essential.

- Manufacturing Process:

3.1 Circuit Board Design:

Creating a well-designed circuit board is crucial for the proper functioning of the electronic relay. Factors such as trace width, component placement, and grounding techniques should be considered to minimize signal interference and maximize performance.

3.2 Component Selection and Soldering:

Choosing high-quality components and employing proper soldering techniques are vital for the reliability and durability of the electronic relay. Attention to detail during the assembly process ensures optimal performance and reduces the risk of failure.

3.3 Testing and Quality Control:

Thorough testing and quality control procedures are necessary to verify the functionality and performance of the electronic relay. This includes testing for proper coil operation, contact resistance, and insulation resistance. Any deviations from the desired specifications should be addressed before the relay is considered ready for use.

Conclusion:

Designing and manufacturing an electronic relay requires a deep understanding of its components, working principles, and practical considerations. By following the guidelines outlined in this comprehensive guide, you will be equipped with the knowledge and skills necessary to create high-quality electronic relays tailored to your specific needs. Remember to prioritize safety and quality throughout the process, ensuring reliable and efficient operation in various applications.