In modern industrial production, flanges are widely used in many industries such as petroleum, chemical industry, shipbuilding, pipeline engineering, etc. as an important connecting element. The flange facing machine is a special equipment for processing flange end faces. Whether its selection is appropriate directly affects production efficiency and product quality. Therefore, it is crucial to understand how to choose a suitable flange facing machine. This article will discuss in detail how to make this choice from multiple aspects.

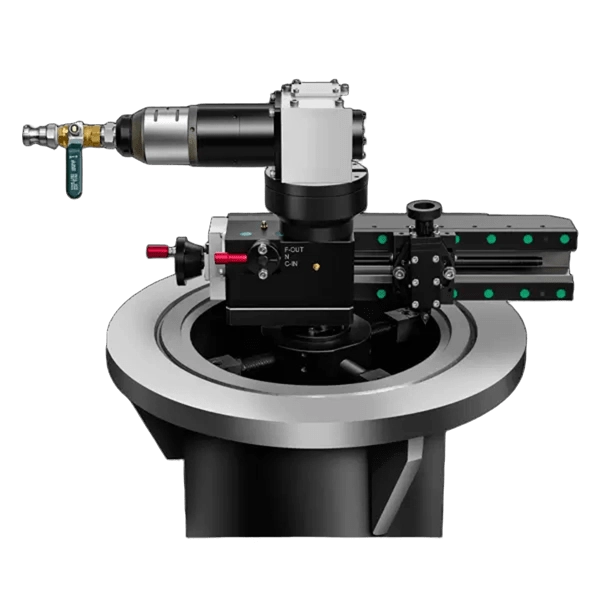

First, the performance of the machine needs to be considered when choosing a suitable flange facing machine. Performance includes processing accuracy, processing range, processing speed and other aspects. Processing accuracy is an important indicator to measure the performance of the flange facing machine, which directly affects the processing quality. Generally speaking, the higher the processing accuracy, the better the processing quality. The processing range refers to the maximum and minimum diameters of the flange connection surface that the flange facing machine can process. Choosing a machine with a suitable processing range according to actual needs can improve work efficiency. Processing speed refers to the processing efficiency of the flange facing machine. Generally speaking, the faster the processing speed, the higher the production efficiency. Therefore, when choosing flange facing machines, it is necessary to consider the performance indicators of the machine according to actual needs to ensure that the machine can meet the work requirements.

Secondly, the processing requirements need to be considered when choosing a suitable flange facing machine. Processing requirements include processing materials, processing forms, processing accuracy and other aspects. Different materials have different requirements for flange facing machines. For example, materials with higher processing hardness require machines with strong processing capabilities. Processing forms include plane processing, bevel processing, groove processing, etc. Choosing a suitable machine according to actual needs can improve processing efficiency. Processing accuracy is determined according to actual needs. Generally speaking, the higher the processing accuracy, the better the processing quality. Therefore, when choosing a flange facing machine, it is necessary to determine the processing capacity and processing accuracy of the machine according to the processing requirements.

After-sales service is a factor that cannot be ignored when choosing a flange facing machine. Good after-sales service can ensure that problems encountered during the use of the equipment are solved in a timely manner, thereby reducing downtime and maintenance costs. Choose a supplier with good reputation and rich experience who can provide high-quality products and services. You can understand the reputation of the brand by consulting user reviews, consulting professionals, etc., so as to make a better choice.

Finally, when choosing a flange facing machine, you should consider the cost-effectiveness comprehensively. Price is not the only determining factor. You need to choose cost-effective equipment on the premise of meeting the needs. The prices of equipment of different brands and models vary greatly, and you should choose the appropriate equipment according to your own budget. In the same price range, choose equipment with better performance.

In summary, choosing a suitable flange facing machine requires a comprehensive evaluation from multiple aspects, such as clarifying needs, choosing the right machine model, considering equipment performance, paying attention to after-sales service, and comprehensively considering cost performance. Choosing a suitable flange facing machine can improve work quality and production efficiency, which is of great significance to the development of the enterprise.

As a flange facing machine manufacturer, we are committed to providing high-quality and reliable products to meet the needs of our customers. We have advanced production equipment and a technical team that can design and manufacture flange facing machines of various types and specifications. Our products are strictly quality controlled to ensure that they are stable and durable in performance and meet international standards and industry requirements

https://www.nodha.com/

NODHA