Mechanical seals are an essential component in many industrial applications, including pumps, compressors, and mixers. They are used to prevent leakage of fluids and gases, ensuring the safe and efficient operation of machinery. In this article, we will explore the mechanics behind mechanical seals, their types, and their applications.

What are Mechanical Seals?

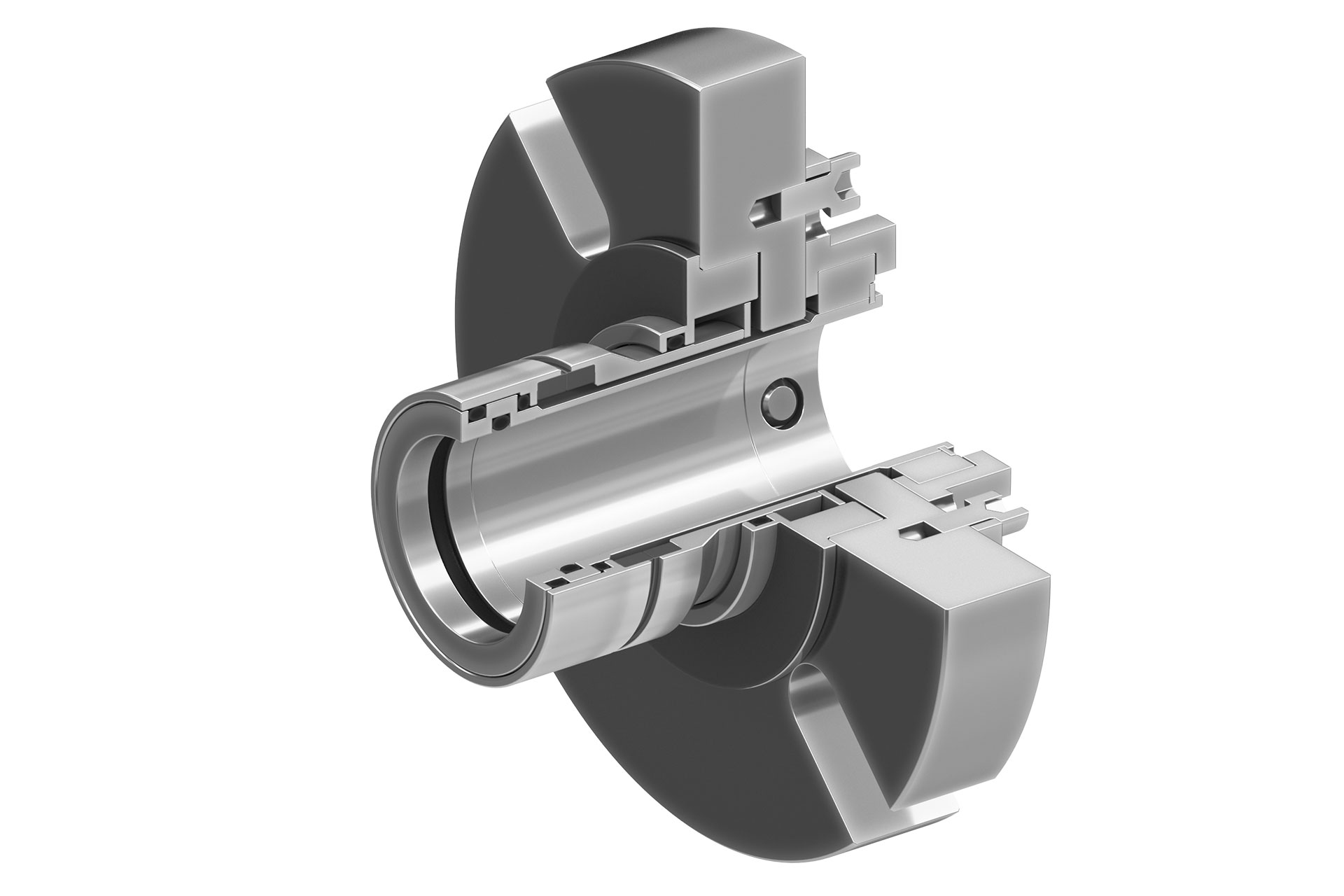

Mechanical seals are devices that create a barrier between two surfaces to prevent the leakage of fluids or gases. They consist of two main components: a stationary part and a rotating part. The stationary part is typically mounted on the pump or compressor housing, while the rotating part is attached to the shaft. The two parts are held together by a spring, which creates a seal between them.

How do Mechanical Seals Work?

Mechanical seals work by creating a seal between the stationary and rotating parts. The seal is created by applying pressure to the two surfaces, which compresses the seal faces together. The pressure is created by a spring, which is compressed when the two parts are brought together. The seal faces are typically made of hard materials, such as ceramic or tungsten carbide, which are resistant to wear and corrosion.

Types of Mechanical Seals:

There are several types of mechanical seals, including single, double, and cartridge seals. Single seals are the simplest type and consist of a stationary and rotating part. Double seals are used when a higher level of safety is required, as they provide an additional barrier against leakage. Cartridge seals are pre-assembled and can be easily replaced, making them a popular choice for applications where downtime is critical.

Applications of Mechanical Seals:

Mechanical seals are used in a wide range of industrial applications, including pumps, compressors, mixers, and agitators. They are also used in the automotive and aerospace industries, where they are used to seal engines and transmissions. Mechanical seals are essential for preventing leakage of fluids and gases, ensuring the safe and efficient operation of machinery.

Conclusion:

Mechanical seals are an essential component in many industrial applications, providing a barrier against leakage of fluids and gases. They come in several types, including single, double, and cartridge seals, and are used in a wide range of industries, including pumps, compressors, and mixers. Understanding the mechanics behind mechanical seals is essential for ensuring the safe and efficient operation of machinery.